Powder coating VS Spray Painting and the relative filters

Powder coating VS Spray Painting and the relative filters

Powder coating is achievable with either thermoplastics or thermosets. The former is a chemical-free process that relies on heat to bring the powder to its thick, solid-coat state. With thermosets, chemical additives interact with the powder during the application stage. The end result of thermoplastic and thermoset powder coatings are virtually identical. In both processes, you heat the powder to form the color finish on a chosen surface.

It`s durable, fast, diverse colors, eco-friendly and consistent.

Well, traditionally, industrial color coats have been achieved through the self-explanatory process known as spray painting, where paint is applied in aerosolized form through pump devices at high pressure. In the majority of applications, the paint is delivered via pneumatic-powered tools or machinery to achieve a consistent, even coat along a chosen surface.

It`s self-drying without heating, thinness texture and affordable.

Well, as for air filters, what difference are there between them?

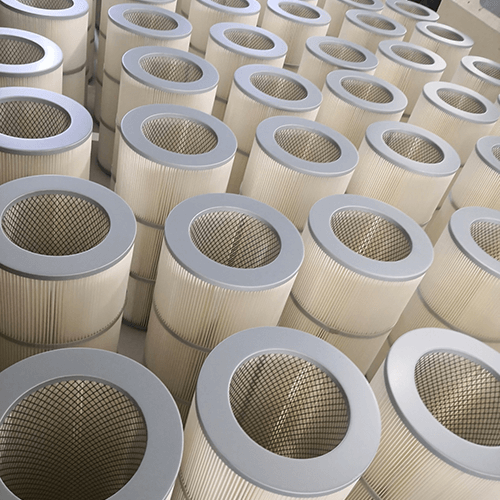

As for powder coating, as it`s powder and we can use filter cartridges with pulse clean feature. Then this filter can be used again and again (as attached).

As for spray painting, as it`s wet paint and we can only use paint arrestor filters as follows.

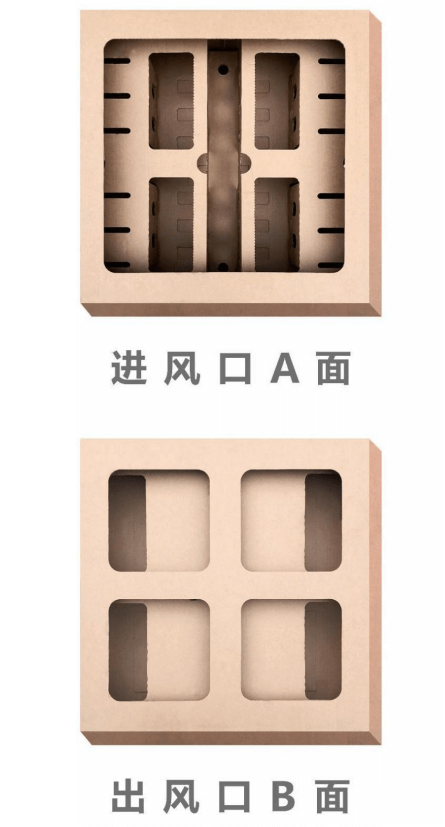

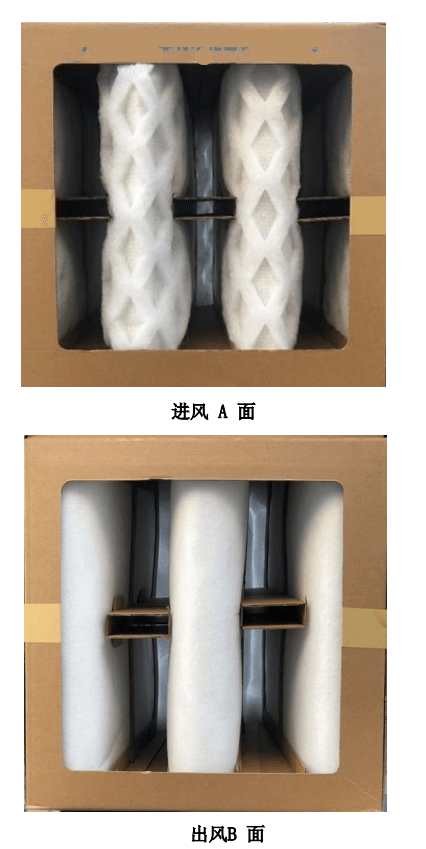

Paint arrestor:

Paint mist collector box:

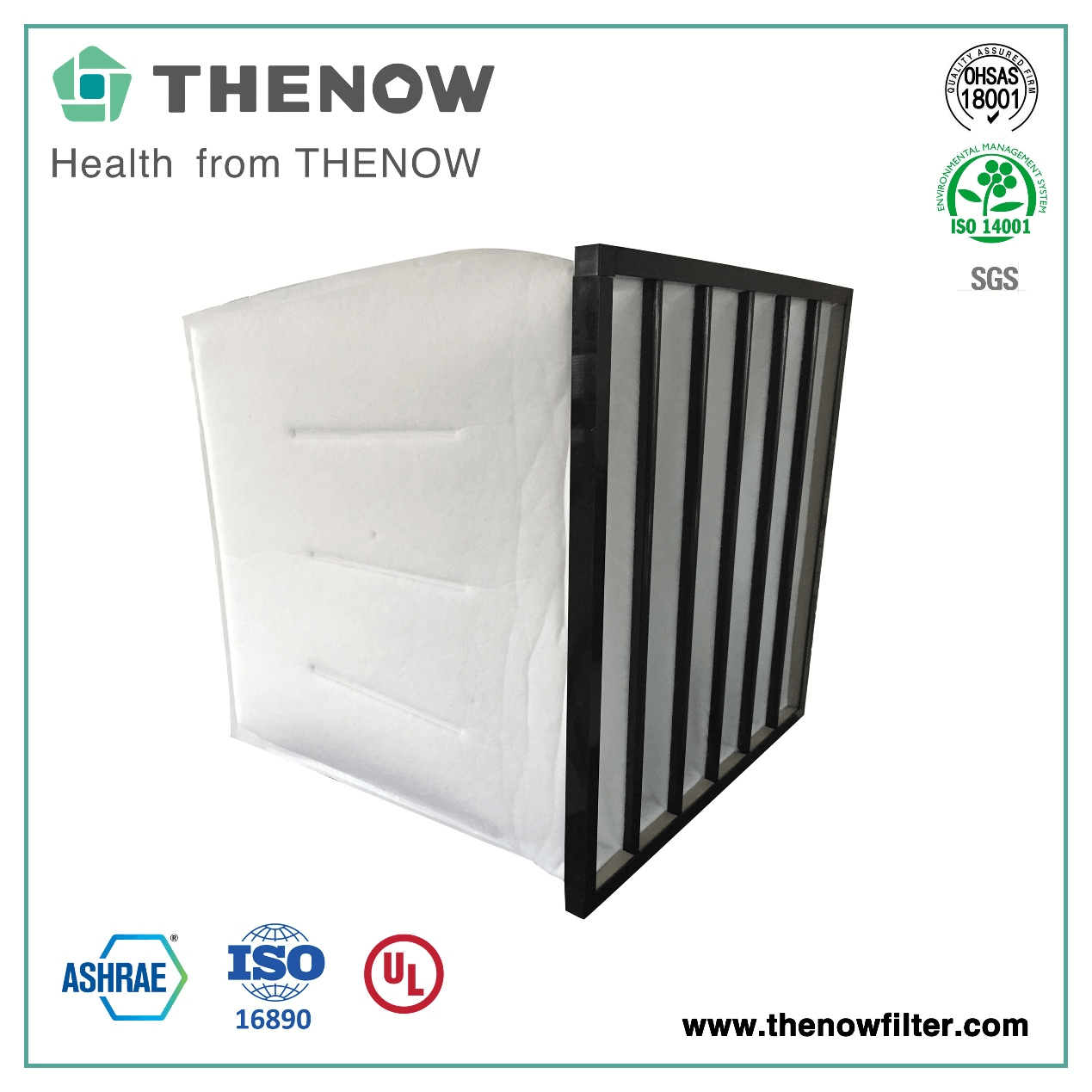

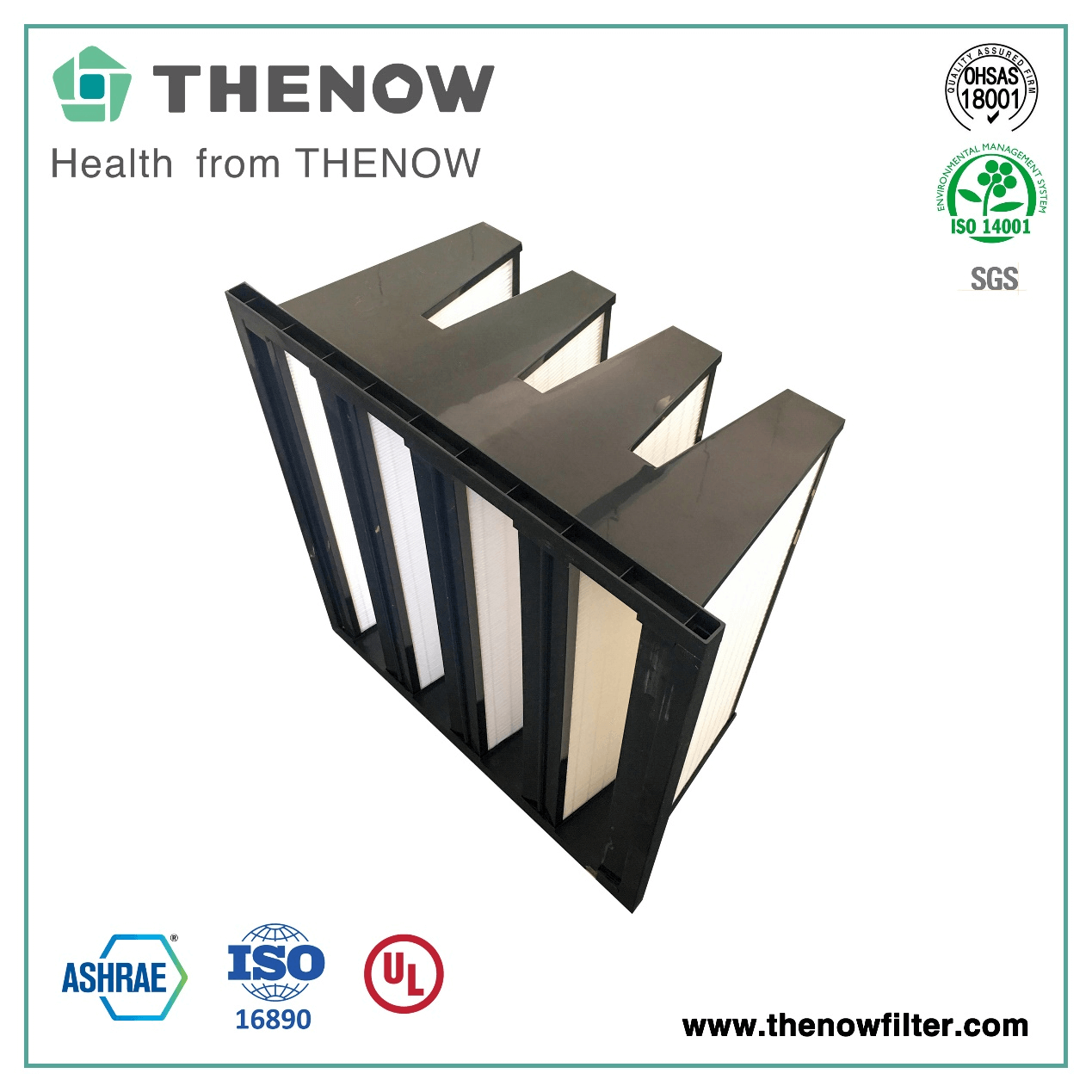

Also as for the ventilating system for painting booth, there also must be some air filters such ceiling media, pocket filters and V bank filters.

News

Copyright © Shanghai Thenow Purification Technology Co.,Ltd. Technical by Singoo

Product Catalog