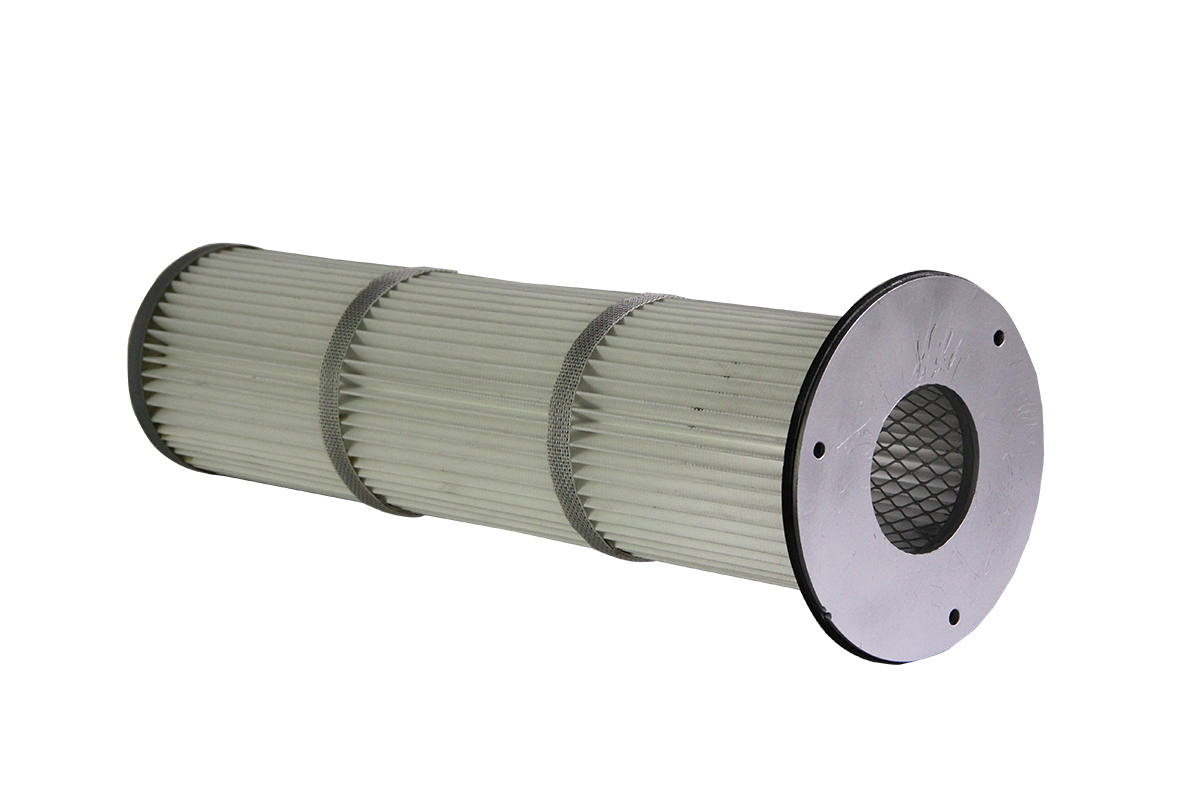

1. Uniform pleats;

2. Qualified filter media;

3. Advanced machine to keep the pleats well done;

4. Enough melt glue and thick end caps to ensure its toughness.

5. By our state-of-the-art air filter laboratory, we guarantee the products with low pressure drop and long lifespan.

Structure:

| Item | Material(Standard) | Material(Alternative) |

|---|---|---|

| Filter Media | Cellulose/Synthetic fiber/ | All kinds of H&V air filtration`s filter |

| Nanofiber/Polyester fiber | media selection | |

| Top cap/ | Galvanized steel | Stainless steel,Color-coated steel, |

| Bottom cap | recyclable plastic ABS | |

| (Open/Closed) | ||

| Gasket | EPDM | Urethane/Silicone |

| Inner Mesh | Galvanized steel | Stainless Steel,Color-coated steel, |

| Recyclable PP | ||

| Outer Straps/Outer | Optional | Galvanized steel,Stainless Steel, |

| Mesh | Glued or ultasonic straps | |

| Finishing Treatment | Teflon-coating,waterproofing,oilproofing,flame-retarding | |

| treatment, antistatic coating,etc | ||

There are following applications:

| 1.Cement and rock |

|---|

| Crush/Grind Coal mill Raw mill/Cement mill Clay crushed |

| Packaging machine Bentonite crushed Kaolin processing |

| Ventilation and dust removal of silo top Material handling / shipping |

| 2.Aluminum plant |

| Fluidized bed dry-cleaning tower The venturi jet dry-cleaning tower |

| Self-baking dry-cleaning tower Carbon dust processing |

| Broken and ventilation of anode Reaction / non-reaction mine shafts prebaked |

| 3.Food / Medical |

| Food Additives Cereal drying Protein spray drying Grain processing |

| Flour Animal vitamins Sugar-coated tablets |

| 4.Metallurgy |

| Electric arc furnace Blast furnace Sulfur removal furnace Casting machine |

| Induction furnace Mold cooling line Blasting / Polishing Drum furnace |

| Sand production/recycling |

| 5.Chemical industry |

| Fertilizer spray drying Plastic fiber Bleaching powder Cellulose |

| Polyethylene resin Polystyrene staple Coke / briquettes processing Packaging line |

| Tire / Special rubber PVC Catalyst processing |

| 6.Paint / Pigment |

| Black powder mixing / agitation Packaging line Pneumatic conveying Paint mixing |

| Pigment stir Spray drying Micro powder mill |

|

Model |

Filter area(m²) |

Length(M) |

Temperature(℃) |

Media Weight(g/m²) |

Air permeability |

Media type |

|

TN-P1 |

2.3 |

1 |

135 |

270 |

7m3/m2/min@12mm WC |

Spun bond polyester |

|

TN-P2 |

4.6 |

2 |

135 |

270 |

7m3/m2/min@12mm WC |

Spun bond polyester |

|

TN-D1 |

2.3 |

1 |

135 |

270 |

7m3/m2/min@12mm WC |

Antistatic spun bond polyester |

|

TN-D2 |

4.6 |

2 |

135 |

270 |

7m3/m2/min@12mm WC |

Antistatic spun bond polyester |

|

TN-F1 |

2.3 |

1 |

135 |

270 |

7m3/m2/min@12mm WC |

Spun bond polyester+PTFE |

|

TN-F2 |

4.6 |

2 |

135 |

270 |

7m3/m2/min@12mm WC |

Spun bond polyester+PTFE |

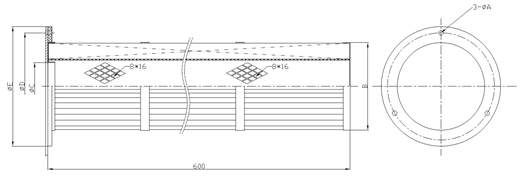

Option Chart for Tube Sheet Holes:

|

Item |

Tube sheet hole diameter |

Top cap size(OD*ID) |

End cap diameter |

|

1 |

φ125 |

142*65 |

110 |

|

2 |

φ127 |

142*65 |

115 |

|

3 |

φ133 |

152*73 |

120 |

|

4 |

φ138 |

156*73 |

125 |

|

5 |

φ143 |

165*80 |

130 |

|

6 |

φ151 |

178*83 |

140 |

|

7 |

φ155 |

178*83 |

142 |

|

8 |

φ162 |

178*83 |

146 |

|

9 |

φ166 |

185*83 |

150 |

|

10 |

φ176 |

194*95 |

160 |

|

11 |

φ206 |

232*105 |

196/200 |

Production Procedure, R&D, Company culture, Factory Virtual Tour and Shipments all over the world.

Exhibitions show: Powtech in Nurnberg & Achema in Frankfurt &Hannover Messe & AHR in Chicago

For more information, feel free to contact us anytime!